Recommendations for proper operation

| M.O. n°37 of 2008, art. 6 – Realization and installation of facilities – (former D.L. 46/90 art. 7). "Companies create facilities following the engineering practice, in accordance with the existing legal framework and are responsible for their proper operation. The created facilities in accordance with the existing legal framework and legal provisions of UNI, CEI or other standardization Bodies – belonging to the other Member States of the European Union or contracting parties in the economic area agreement – are considered as performed following the engineering practice." |

|---|

The IRSAP guarantee, for all the products offer, is considered as valid and accordingly applicable, in case of compliance with all the relevant standards and regulations – that have to be standards into force – for a correct installation. In particular, the Ministerial Order related to the creation of heating facilities for civilian use is the n°37 of January 2008. This Decree, through its articles, incorporates and includes few technical measures issued in favor of the UNI (the Italian Body of Unification) and the CTI (the Thermotechnic Italian Committee). The attention is to be focused on the UNI 8065 regulation of 1989 (transposed by the M.O. 37/2008) as "Water treatment in heating installations for civilian use". This regulation forces a water treatment for all the technical installations for civilian use, both for open and closed-cup. The UNI 8065 provides some important directions about the operation and maintenance of heating installation. A few examples are 6.1.1, 6.1.3 and 6.1.4, which specify in detail:

ART 6.1 - Hot water-supplied heating system

• 6.1.1 - Treatments required

For all systems, it is necessary to predict a chemical conditioning. For those systems more powerful than 350 KW (300.000 Kcal/h), it is necessary to install a security filter (that is recommended for all) and, in case the water has a total hardness greater than 15°F, install a softener filter to restore the limits of 6.1.3.

• 6.1.2 - Intervention

The treatment systems need to be installed upstream the protected systems, on the load and restoration pipelines, in order to treat both the first filling water and the one of the next topping-ups. The feed-in point of the chemicals needs to be planned in order to ensure a possible speed of action. The ideal feed-in point is in the principal flux of the system, in an area of maximum turbulence, such as upstream of the flow pumps.

• 6.1.3 - Specifics of the first filling water and the one of the next topping-ups

Aspect: clear

Total Hardness: under 15°C

NOTE: for the heating systems with power under 350 KW (300.000 Kcal/h), the softener can be replaced by a suitable chemical, in case the first filling water and the one of the next topping-ups has a hardness under 35°C.

• 6.1.4 - Specifics of the water loop

Aspect: possibly clear

pH: greater than 7 (with radiators with aluminium units in right alloys, the pH needs to be under 8) Chemicals: within prescribed limitations

Iron (Fe) < 0,5 mg/kg (higher values due to corrosion to be removed).

Copper (Cu) < 0,1 mg/kg (higher values due to corrosion to be removed).

Softened water needs to be filled with chemicals, because it can become aggressive. Use only suitable products, such as silicone rubbers, to prevent the radiator gaskets to be corroded. Remove all the products, after use.

After testing a few products, IRSAP recommends DEFENDER line.

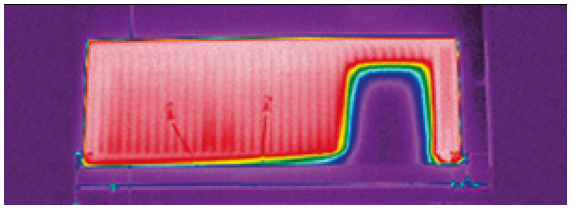

CLEANING EFFECTS

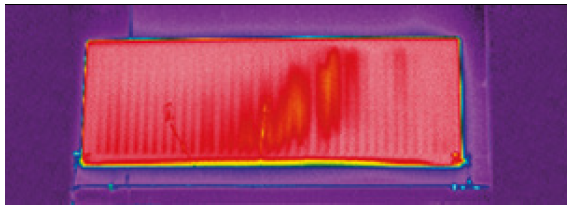

Increasing the water temperature, precipitations of calcium and magnesium salts deposit on the metal surfaces of pipelines, on coils of water heaters and heat exchangers. The effect is the sharp decrease of the installation capacity and the heat output. The limestone fouling is a wall for the heat transmission. Moreover, inside the radiators on very old systems, there could be areas of deposit, where water does not flow. Our products, working with the operating system, remove those leftovers and restore the full functionality of the radiator (see the pictures – before and after a Defender product).

BEFORE: Cold area due to mud

AFTER: Removal of cold area.